This troubleshooting guide is intented to help identify and repair problems with the cooling system. The following is a list of problem symptoms discussed in this guide:

| Possible Causes |

Checks |

Procedure |

| Improper coolant level |

Check coolant level and fill if necessary.

|

N/A

|

| Cooling fans, thermofan switch, or fan relay not operating correctly. |

Check cooling fan operation using COOL-01.

|

COOL-01

|

| Air in cooling system. |

Fill and vent cooling system using COOL-02.

|

COOL-02

|

| Head gasket. |

A leaking head gasket can allow cylinder gasses to pressurize the cooling system. This will void the area around the cooling jackets, overpressurize the cooling system, and cause the reservior cap to relieve coolant which result in overheating. This may appear to be a coolant leak at first. This can often be identified by a compression test or cylinder leakdown test. Another method of identifying this leak is to take the car to a radiator shop and have them test the coolant for the presence of exhaust gasses.

|

N/A

|

| Faulty thermostat. |

Remove and test the thermostat using COOL-08.

|

COOL-08

|

| Wrong Thermostat. |

When Porsche changed the water pump on later 944s, the depth of the snap ring groove from the thermostat sealing surface changed. This required the use of a different thermostat and thermostat sealing ring. If you get the wrong thermostat it can cause cooling problems. This is described in COOL-07.

|

COOL-07

|

| Bad water pump. |

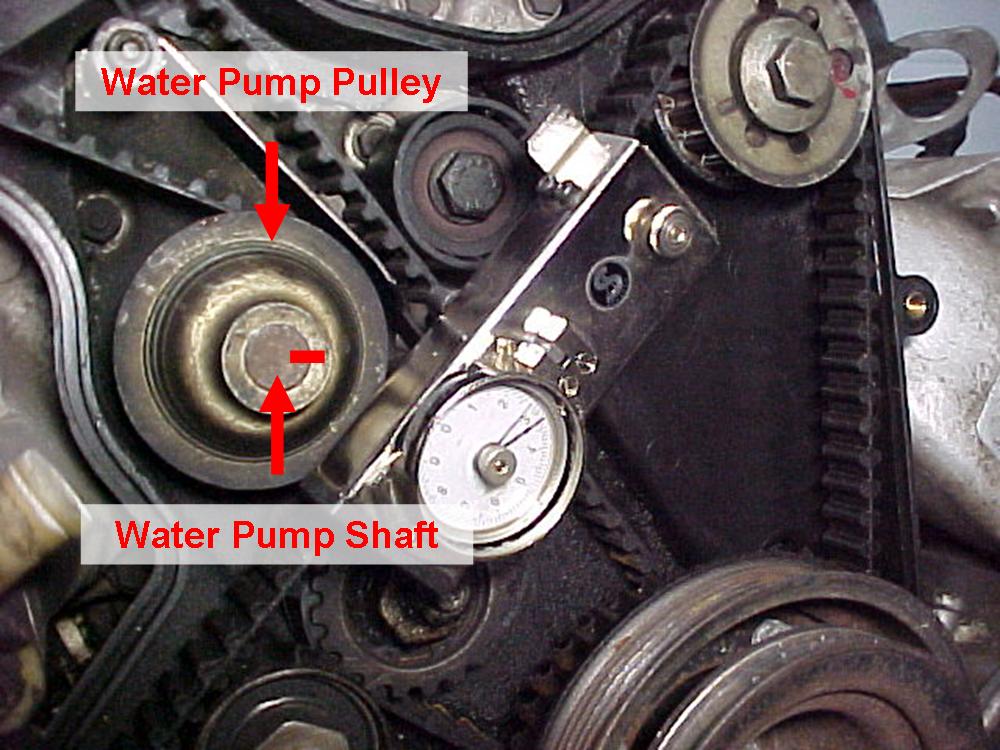

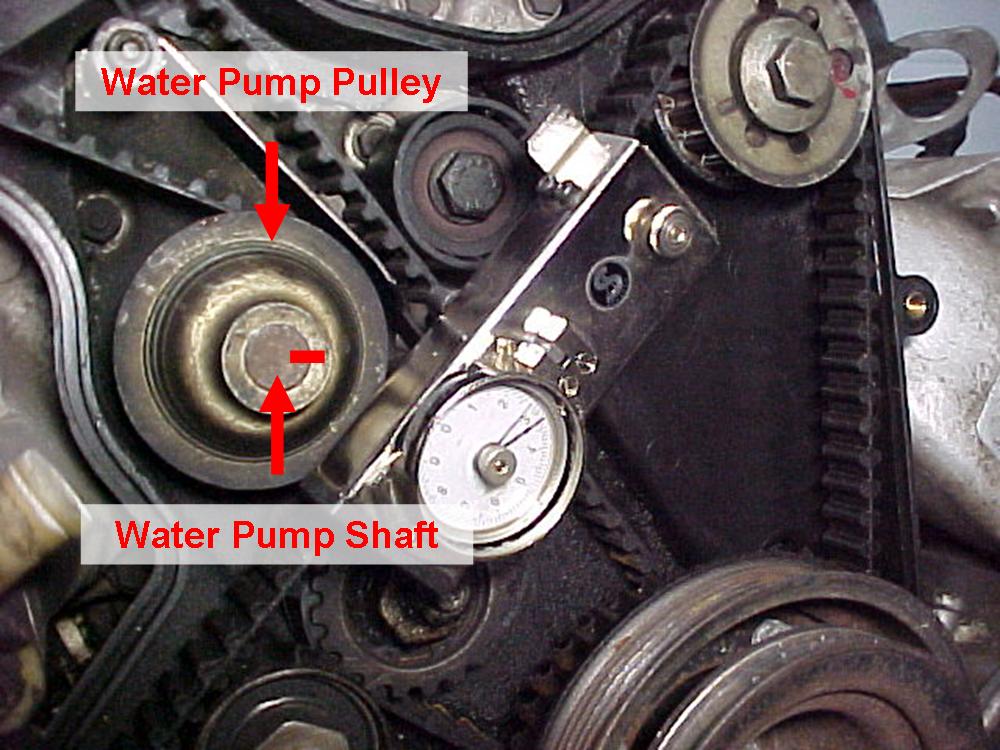

This is a somewhat unusual problem and difficult to identify. Apparently, with some rebuilt water pumps, the pulley will sometime slip on the water pump shaft. This is particularly true with a fresh rebuild where the water pump seal is a bit tight.

To check for this problem, remove the top timing cover and locate the water pump pulley. When you look at the pulley you'll see the end of the water pump shaft in the center of the pulley. Using a paint pen, permanent marker, or brightly colored finger nail polish, place a mark across the end of the pump shaft and pulley. When you start the engine, if the pulley is slipping the mark on the shaft and the mark on the pulley will NOT remain aligned. If you discover that the pulley is slipping it is possible to correct this by placing a tack weld on the end of the water pump shaft where it meets the pulley. Make sure you put a tack weld on opposing sides of the shaft where it meets the pulley so the pump will remain balanced.

|

N/A

|

| Faulty coolant reservoir cap. |

If the coolant reservoir cap does not hold it's correct pressure, the coolant in the cooling system can boil causing voids in the system and overheating. Remove the cap and check that it opens at the pressure stamped on the cap (normally in millibars) and not significantly below it. You may have to convert the millibars stamped on the cap to PSI depending on your location. If you can't borrow a coolant pressure tester, take the cap to a radiator shop or major auto parts store and have them test it for you.

|

N/A

|

| Radiator internal passages blocked or excess debris on outside of radiator. |

Remove the radiator using COOL-04. Take it to a professional radiator shop and have it tested and if necessary cleaned.

|

COOL-04

|

| Possible Causes |

Checks |

Procedure |

| External Leak |

Leaks external to the engine seem like they would be very easy to locate. However, leaks will often not appear until the coolant system is fully pressurized. Since that only happens when the engine is run to normal operating temperature, the heat generated in the engine compartment can make it difficult to look for leaks. If you can borrow or rent a coolant pressure tester to pressurize the system while it is cold, it makes it much simpler to look for leaks.

Possible Leak Locations:

- Coolant hoses (i.e. radiator, heater control valve, return from heater core at back of engine compartment)

- Water Pump (may require removing upper timing cover)

|

N/A

|

| Internal Leak |

Generally and internal leak can result in coolant leaking into the cylinders or into the oil system at an oil-water interface.

Possible Leak Locations:

- Head Gasket

- Oil Cooler Seals

- Cracked Cylinder Wall

Generally, internal leaks are primarily the head gasket leaking allowing coolant to enter the cylinder. These can be identified by large amounts of white smoke coming from the exhaust. Also, you can remove the spark plugs one at a time and look for a "wet" spark plug that smells like anti-freeze. Head gasket leaks can also be identified by performing a compression test or cylinder leakdown test. Cracked cylinder wall leaks will cause the same symptoms but, are extremely rare.

Leaks that allow coolant to enter the oil system are somewhat unusual because the oil system normally operates at a much higher pressure than the coolant system. So, head gasket or oil cooler leaks typically first appear as oil in the coolant (milk shake) as opposed to coolant in the oil. Normally, the only time you see coolant in the oil first is when there is a sudden catastrophic head gasket or seal failure immediately after engine shutdown.

|

N/A

|